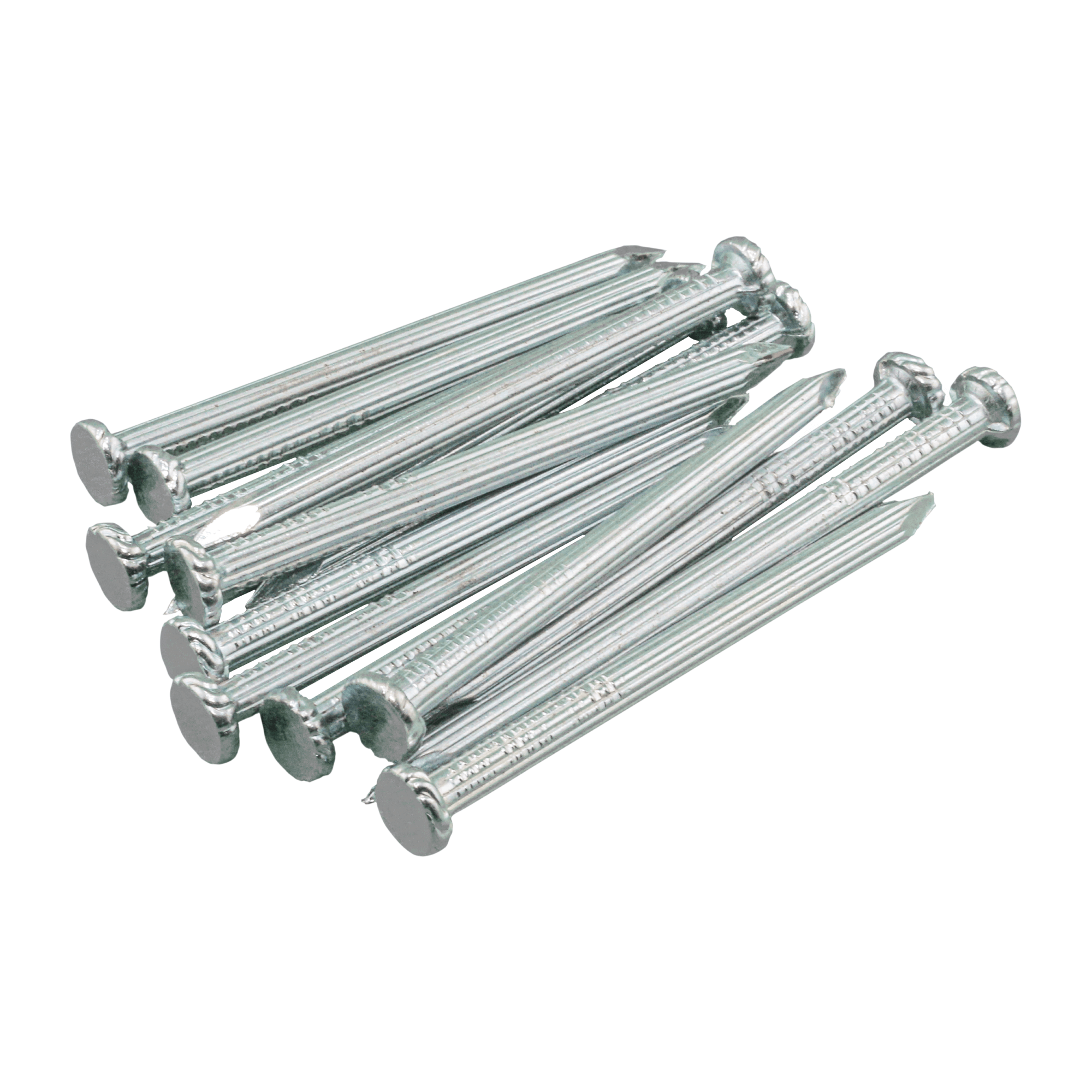

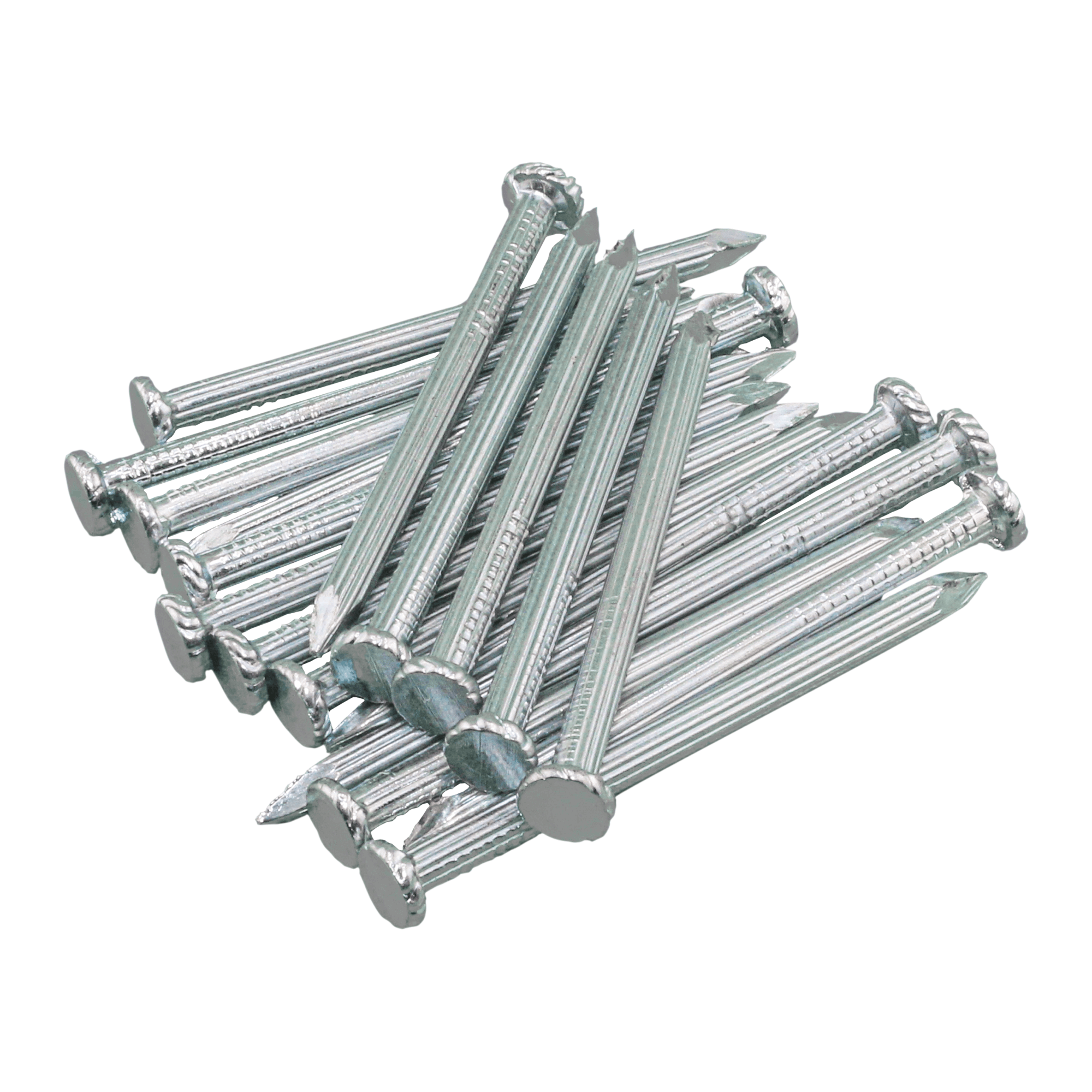

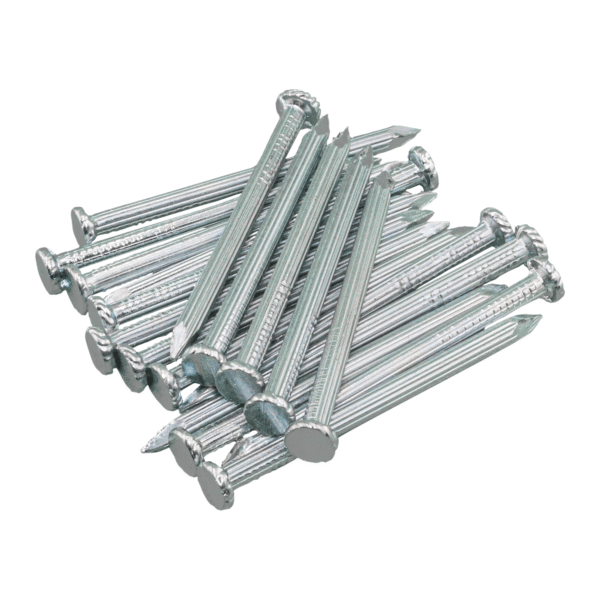

ตะปูคอนกรีต Concrete Nails

- Material : Medium Carbonsteel wire TIS-349

- Flated-head, Diamond Point

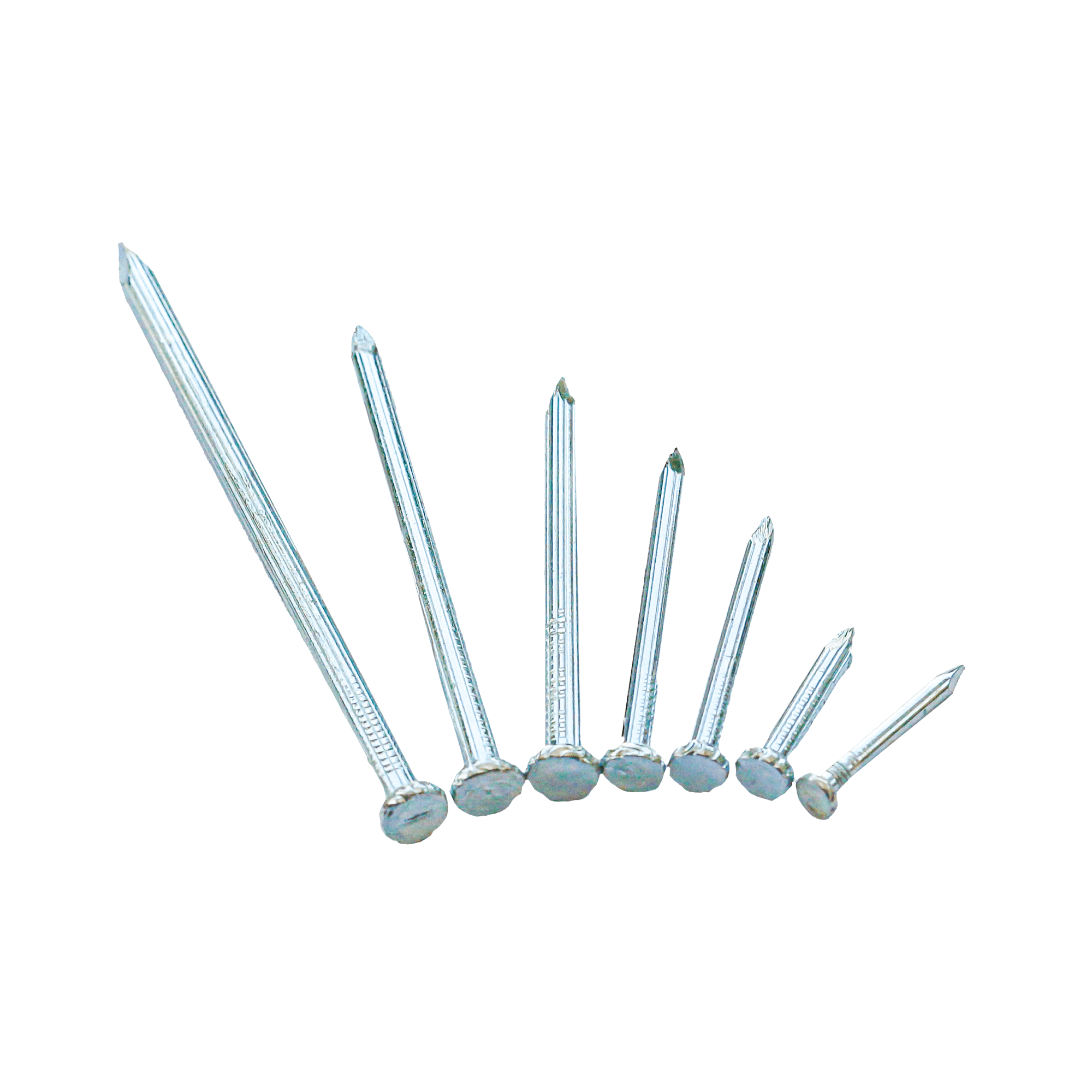

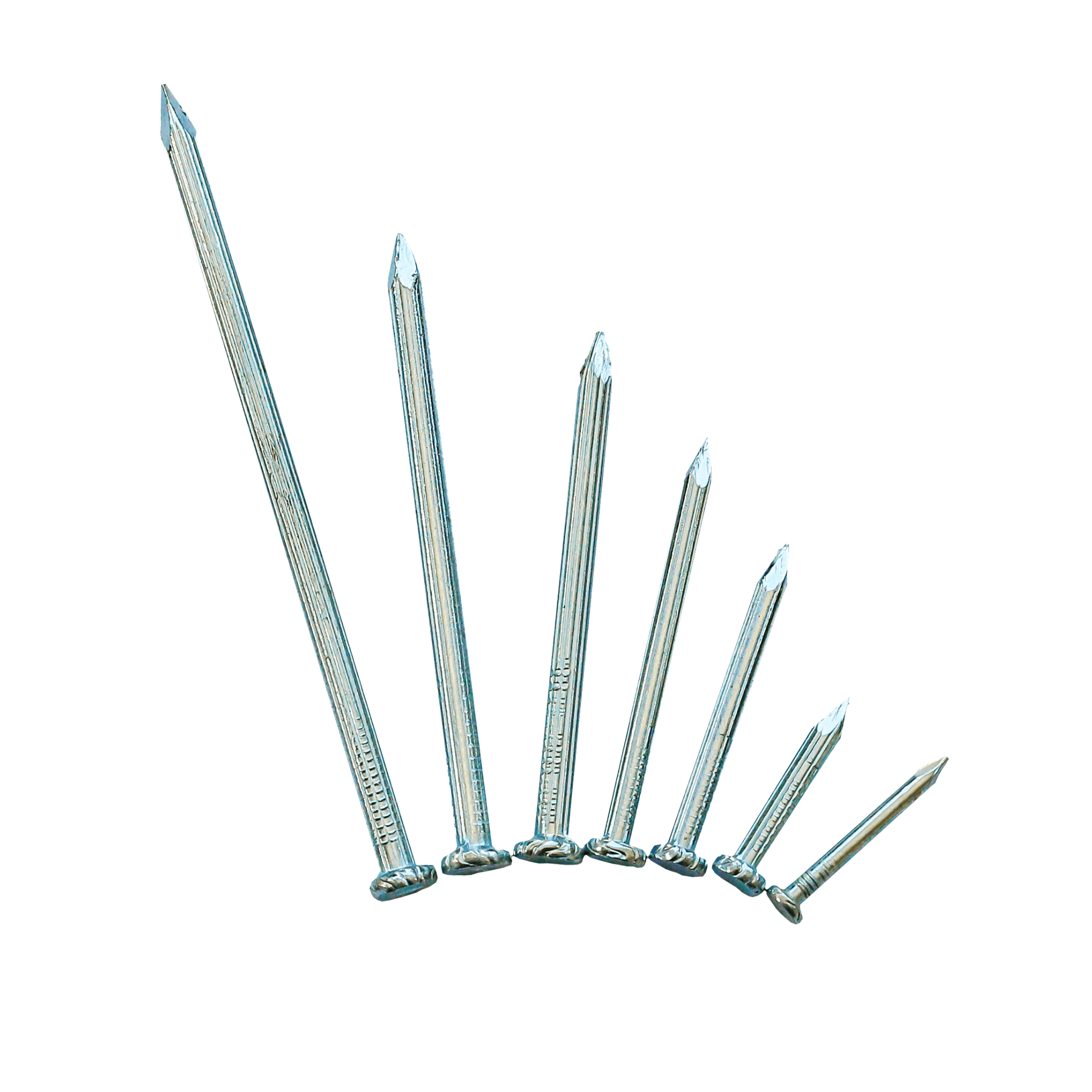

- Length : 1″ - 4″

- Coated : Electroplating Zinc

- Packing : 20 Boxes / Carton (1 Kg per box)

- Application : To use with concrete walls and blocks in construction work

| Size | Size(mm) x Length(mm) |

| #12×1″ | ⌀2.76 mm. x 25 mm. |

| #12×11⁄2″ | ⌀2.76 mm. x 38 mm. |

| #9×1″ | ⌀3.75 mm. x 25 mm. |

| #9×11⁄2″ | ⌀3.75 mm. x 38 mm. |

| #9×2″ | ⌀3.75 mm. x 50 mm. |

| #8×21⁄2″ | ⌀4.19 mm. x 65 mm. |

| #7×3″ | ⌀4.57 mm. x 76 mm. |

| #7×4″ | ⌀4.57 mm. x 100 mm. |

| #7×4″ | ⌀4.57 mm. x 100 mm. |

| #2.0×18″ | ⌀2.0 mm. x 18 mm. |

| #2.0×25″ | ⌀2.0 mm. x 25 mm. |

What Are Concrete Nails?

Concrete nails are used to fasten clamps or attach items to concrete or precast walls without the need for pre-drilling. They are hardened, zinc-coated for rust resistance, and feature a textured body for better grip. These nails are ideal for construction tasks that regular nails cannot handle.

Choosing the Right Concrete Nails for Your Project

Concrete nails should be made from medium carbon steel and hardened to around 48–52 HRC. Available in various sizes, their length should correspond to the thickness of the material being fastened. Common uses include securing wooden frames, fastening pipe clamps, and hanging objects.

Important Factors to Consider When Purchasing Concrete Nails

- Size:Choose the length and dimensions based on the thickness of the material.

- Coating:Prefer nails with zinc or anti-corrosive coatings for durability.

- Quality:

- Head:Features an R-curve design to enhance strength and prevent breakage.

- Shank:Should be straight, textured, and free from bending or defects.

- Point:Sharp and clean without metal burrs for easy driving.

- Hardness:Should be between 48–52 HRC to prevent bending or excessive brittleness.

Types of Concrete Nails to Consider

- Galvanized Nails:More expensive than regular wood nails but significantly stronger and rust-resistant.

Warning:Avoid cheap nails that may not be properly hardened or made with inferior steel, as these can break easily and pose safety risks.

Applications of Concrete Nails

- Fastening to concrete or precast walls

- Suspending ceiling frames or hardware

- Installing wire clips or general construction work

Precautions When Driving Nails

- Use the right hammer:Choose one suitable for the nail size to maintain control.

- Drive straight:Hammering straight ensures secure fastening and reduces the chance of nail damage.

Tips for Choosing Concrete Nails

- Ensure materials meet industry standards and come from reputable sources.

- Select trusted manufacturers such asSahaporn Charoen Steel Company, a producer with over 50 years of experience.

- Avoid suspiciously cheap nails that might be made using the IF process, resulting in brittle, breakable steel.

- High-quality nails should have a straight body, unbent head, sharp tip, and a clean, rust-free surface.

Benefits of Using “Brand A” Concrete Nails

- Strength and Durability:Manufactured to meet TIS standards with EAF process steel for safety and long life.

- Versatility:Suitable for various tasks like frame fixing, ceiling installs, and general fastening.

- Affordability:Priced accessibly while delivering high value.

- Ease of Use:Easily driven into concrete or wood using a regular hammer.

- Wide Availability:Found in most hardware stores across Thailand.

Committed to Standards, Strong and Durable,

Emphasizing Quality Choose ‘Brand A’ Nails.

Contact Us

Address : 2 Soi Bangkae 8 Bangkae, Bangkae, Bangkok, THAILAND 10160

Tel : +66 24 555 670 / +66 24 555 671

Email : abrandsteelnail@gmail.com

WhatsApp : 66816922100