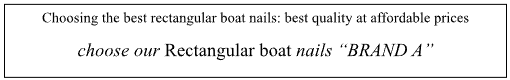

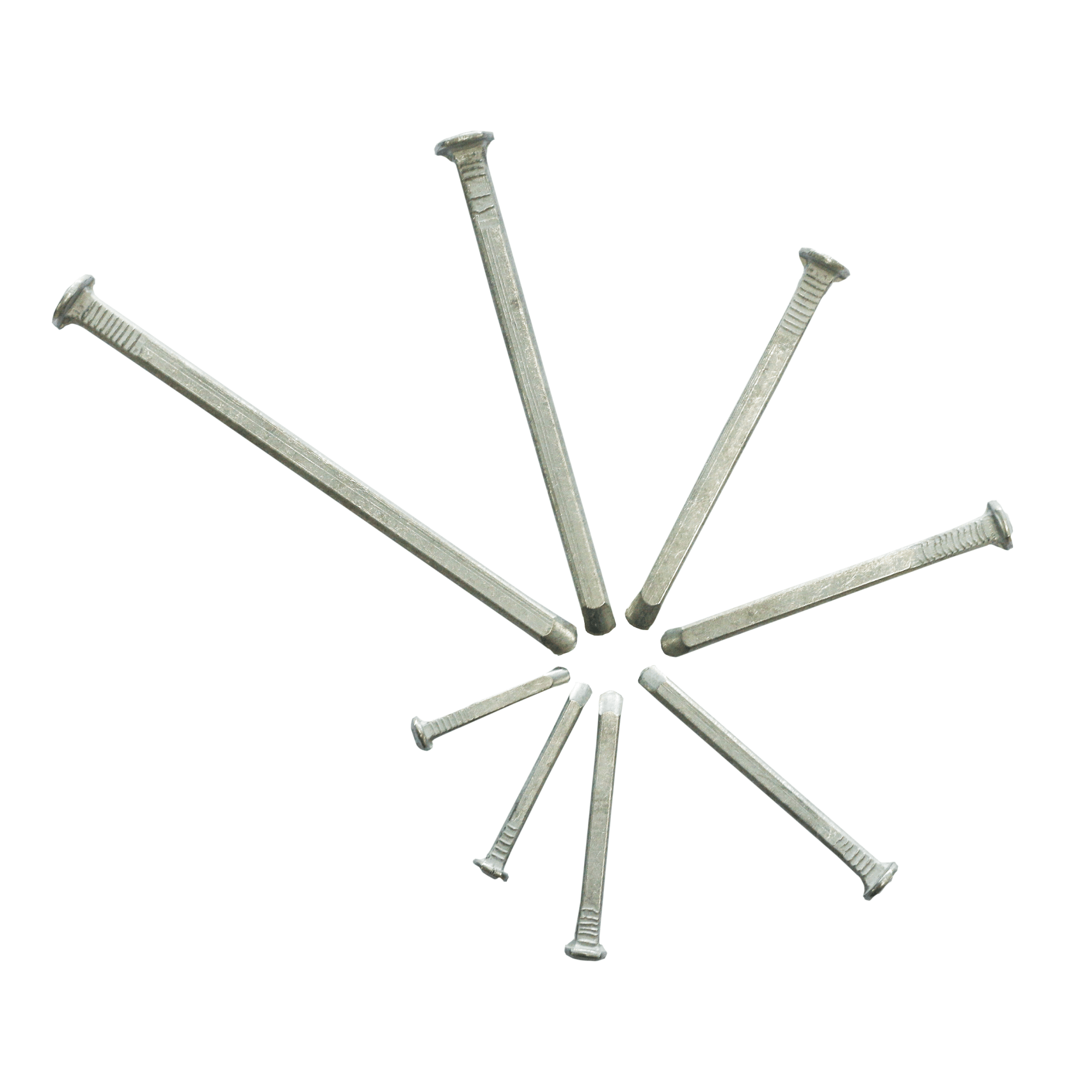

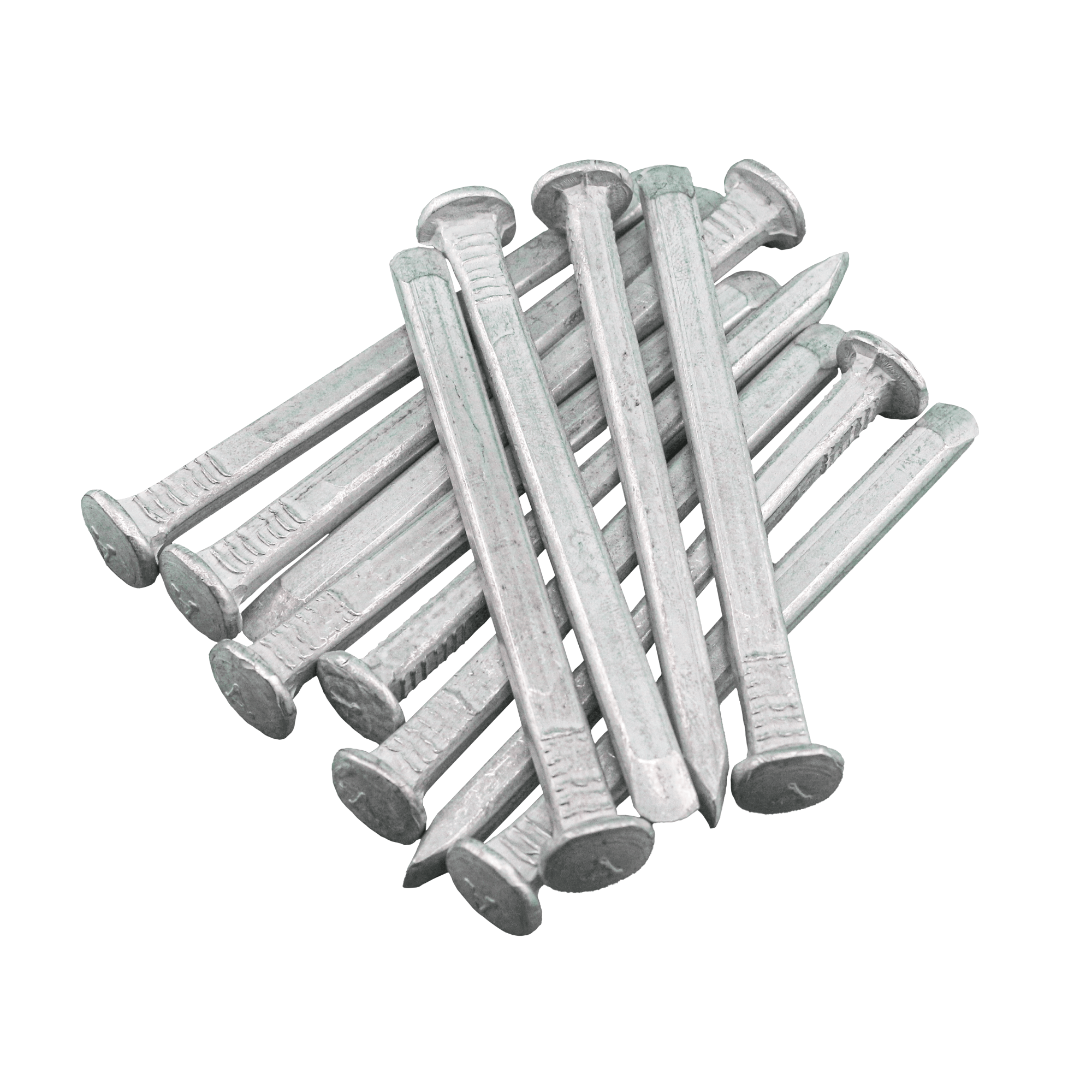

ตะปูตอกเรือแบน Rectangular Boat Nails

- Material : Low Carbonsteel wire (TIS 348-25xx , JIS G 3532 : 2011)

- Round-head, Duck Bill Point

- Coated : Zinc-Coated or Hot-dipped galvanized

- Length : 1 ½″ - 7″

- Packing : 50 Kg per Sack

- Application : To use in building , ship and general construction for fishery

| Size | Size(mm x mm) x Length(mm) |

| #11⁄2″ | 3.9 x 4.8 x 40 |

| #2″ | 4.9 x 5.3 x 50 |

| #21⁄2″ | 5.4 x 6.4 x 65 |

| #3″ | 5.5 x 6.7 x 75 |

| #31⁄2″ | 6.0 x 7.5 x 90 |

| #4″ | 6.2 x 7.8 x 100 |

| #5″ | 7.4 x 8.5 x 127 |

| #6″ | 7.4 x 8.5 x 150 |

| #7″ | 7.4 x 8.5 x 177 |

Understanding the Rectangular Boat Nails: Types, Uses, and Benefits

What Are Rectangular Boat Nails?

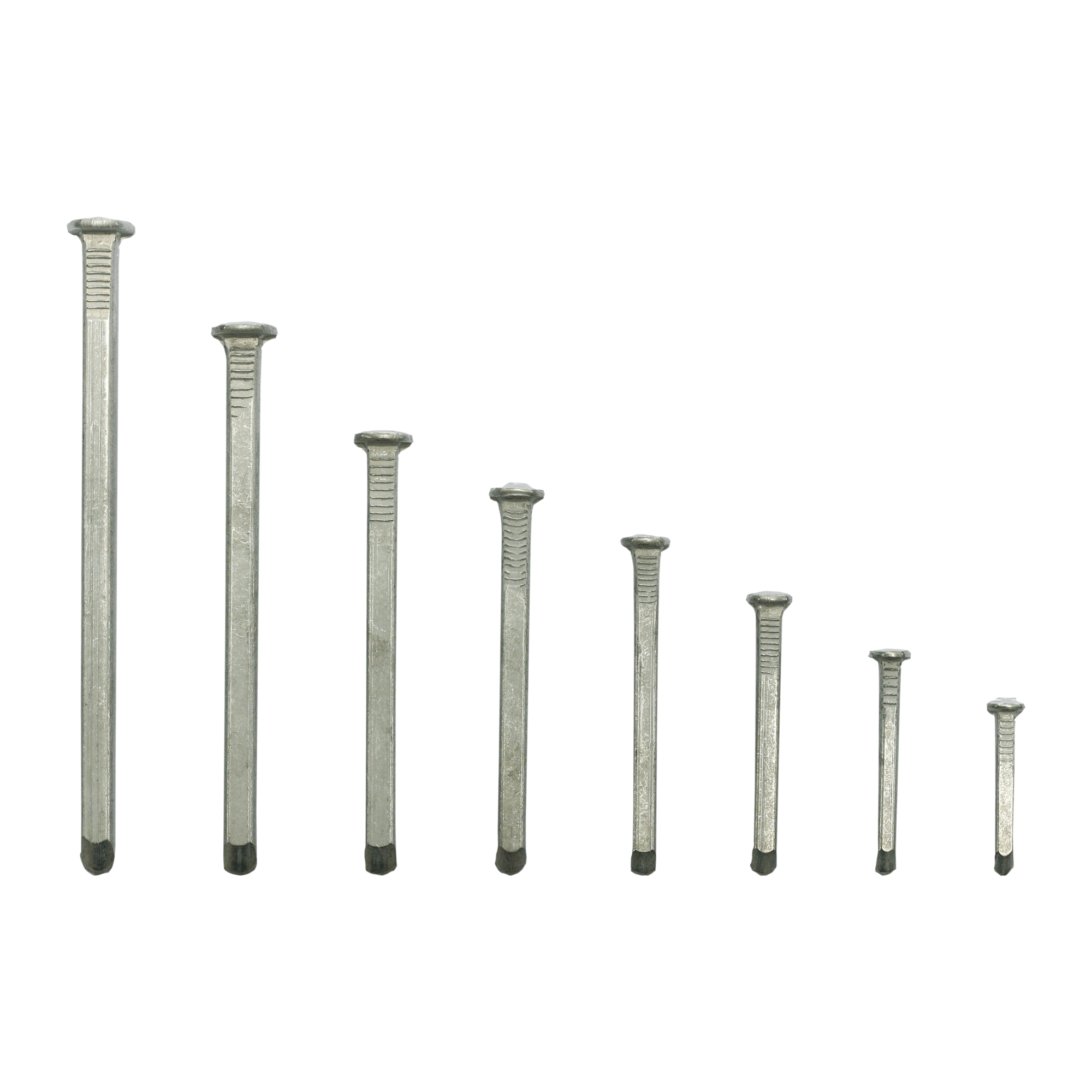

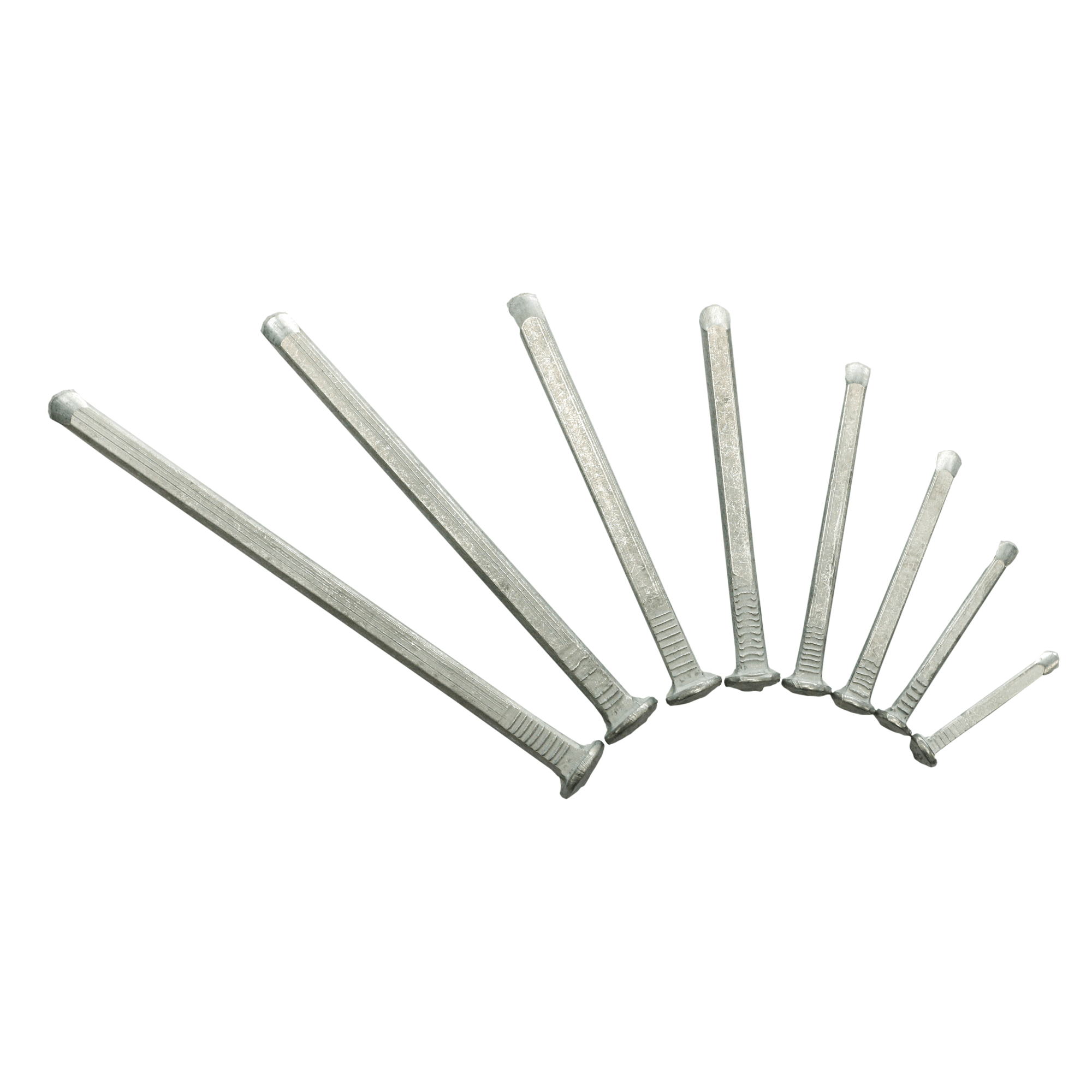

Rectangular Boat Nails or Flat nails are nails made from iron with a flat, rectangular shape. Unlike round wire nails, these have a tapered point that helps secure them more effectively. Historically, they were widely used in the 18th and 19th centuries, particularly in traditional woodworking and shipbuilding.

Important Factors to Consider When Purchasing Rectangular Nails

- Size:Available in various lengths and dimensions, suitable for different material thicknesses.

- Coating:Typically galvanized, but some are lead-coated for better corrosion resistance.

- Quality:

- Head:Should be well-shaped, with a tapered area under the head and an R-curve for added strength.

- Shank:Must be straight and smooth.

- Point:Sharp and clean, without metal burrs.

Types of Rectangular Nails to Consider

- Zinc-coated:Common and affordable, suitable for general use.

- Lead-coated:More expensive, but highly resistant to corrosion and ideal for marine environments.

Applications of Rectangular Nails

- Used in wooden boat construction

- Ideal for heavy-duty woodworking requiring strong fastening

- Common in the shipbuilding industry

Precautions When Driving Nails

- Select the appropriate hammer:Choose the right size and weight for control.

- Drive nails straight:Ensures better fastening and safety.

- Conceal nail heads:Use small-headed nails and wood filler for a clean finish.

Tips for Choosing Rectangular Nails

- Use materials that meet quality standards from trusted manufacturers.

- Choose certified producers. Sahaporn Charoen Steel has over 50 years of experience with a large customer base in Thailand.

- Avoid unusually cheap nails, which may be brittle due to Induction Furnace (IF) processing.

- High-quality nails feature a straight body, unbent head, sharp point, and polished surface free of dirt or oil.

Benefits of Using “Brand A” Rectangular Boat Nails

- Strength and Durability:Withstand high stress, ideal for load-bearing structures.

- Versatility:Suitable for many professional applications.

- Affordability:Competitively priced and sold in bulk.

- Easy to Use:Standard shape allows easy driving with a hammer.

- Availability:Widely available at hardware stores across Thailand.